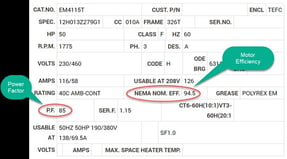

It is relatively easy to calculate how much horsepower a fan is consuming in the field. Once calculated, this information can be used to identify the additional amount of flow and pressure the fan can produce within the limitations of the motor. To perform the calculations, we just need two field measurements which include the motors amperage draw and the line voltage (both can be measured with a voltage meter) and two items shown on the motor’s nameplate. This includes motor efficiency (often shown as “NEMA NOM. EFF.”) and power factor (shown as “PF”).

It is relatively easy to calculate how much horsepower a fan is consuming in the field. Once calculated, this information can be used to identify the additional amount of flow and pressure the fan can produce within the limitations of the motor. To perform the calculations, we just need two field measurements which include the motors amperage draw and the line voltage (both can be measured with a voltage meter) and two items shown on the motor’s nameplate. This includes motor efficiency (often shown as “NEMA NOM. EFF.”) and power factor (shown as “PF”).

Calculating Phase 3 Motor Horsepower

Topics: Fan Performance

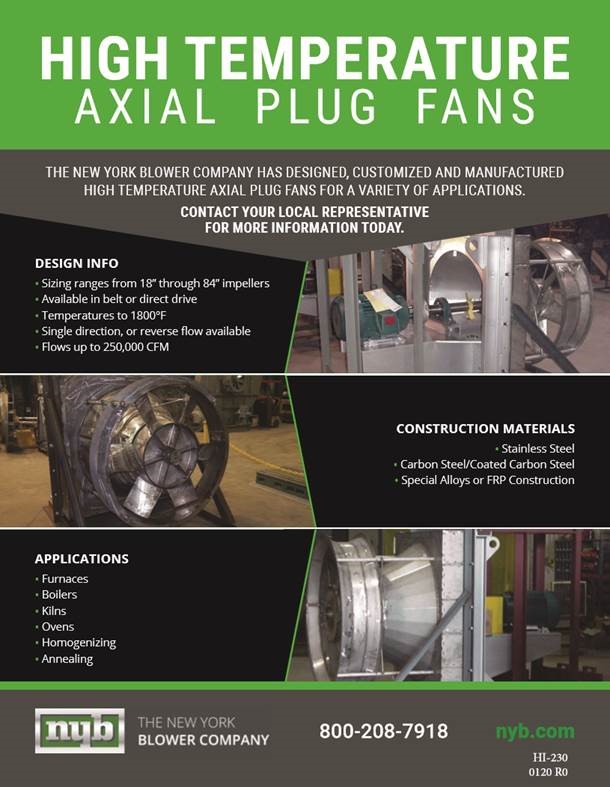

High temperature fans are used for a variety of purposes, typically ranging from 1200F-1800F (650C-980C). Some common industries are aluminum, steel, copper, carbon/charcoal, waste incineration, and others. Fan sizes typically range from 12"-84" (305mm-2130mm) but larger custom fans can be manufactured as well. The common fan types are centrifugal fans with forward curved or paddle style wheels, or axial fans with single-direction or reversing flow construction. Typical arrangements are 1 and 8, with materials ranging based on application demands. For instance, 316 SS can be used for fans up to 1500F, and other materials can withstand different temperature ranges. Some common accessories include insulation between alloy hot surfaces and mild steel cold surfaces, water-cooled shaft, heat slingers, and floating construction to accommodate thermal growth. For more information, talk to your local sales representative or click here.

Topics: Axial Fans

nyb Inducted into the Indiana Manufacturers Hall of Fame

New York Blower Company was inducted into the 2019 Indiana Manufacturers Association's (IMA) Hall of Fame on October 16, 2019, in Indianapolis, at the Biltwell Event Center. New York Blower Company was chosen from a select group of Indiana manufacturers for its positive achievements and contributions to the industry and area community.

Topics: Manufacturing

Manufacturing Day in Effingham (2019)

The Effingham county manufacturing day was held on October 3, 2019. Students, teachers and counselors from area schools attended the event. Local manufacturers, including nyb, hosted tours for all interested participants. Several dozen students toured the nyb facilities. Glen Todd started with a brief introduction of what nyb fabricates and its' operations. James Smith and Jay Amberg conducted tours throughout the facility. While touring, students spent time with Teresa Tabbert learning the CNC machining operations (left picture). Ben Ruholl helped to explain the laser operations (right picture).Rob Werner educated them on robot operations, and Fred Finn and Mike Morrison demonstrated welding operations. Students were given a great opportunity to see manufacturing jobs in their hometown.

Topics: Blog Migrations, Manufacturing

nyb Donates Welding Jackets to Local Welding School

Topics: Blog Migrations

Suqian Facility Open for Production

nyb and Airtrade Singapore PTE. are pleased to announce a joint venture in China - NYB Suqian. Airtrade is the long time licensee for New York Blower in Singapore. The two companies have been continuing to expand operations in Asia, which resulted in requiring more manufacturing space.

Topics: Asia, Joint Venture, China, Centrifugal Fans, Manufacturing, Airtrade, Axial Fans

nyb Donates Fan for Educational Purposes

Dylan Grove is a Senior at EMU. He decided to build a wind tunnel for his senior engineering capstone project. The university will use the tunnel in its fluid mechanics class to model air flow and study lift, drag and other forces on models such as an airplane with an eight inch wingspan.

Topics: Donation, Giving Back, University, Student

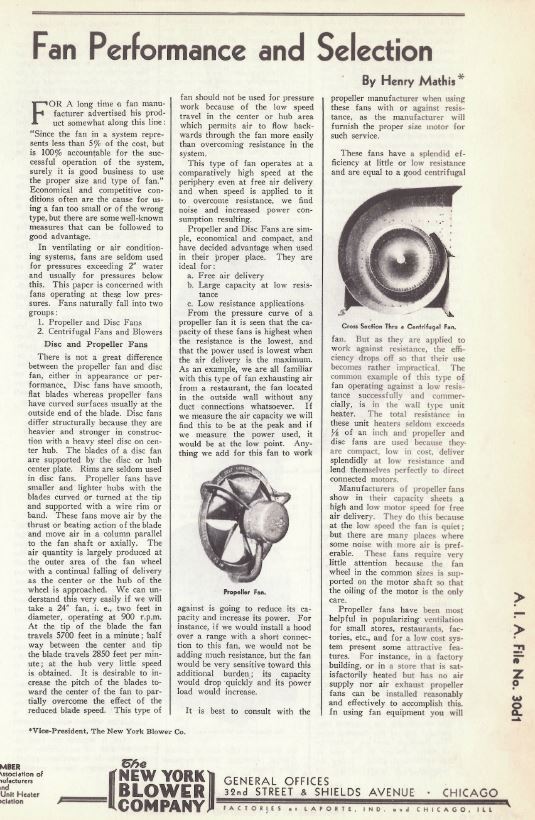

Fan Performance and Selection Article

New York Blower continues to be the experts in the air-moving industry, going back to the founders of the company. Henry Mathis, Vice-President of nyb at the time, wrote an article about Fan Performance and Selection that was originally published in October, 1932 in the publication The Aerologist.

Topics: Fan Performance, Fan Selection, History

AirEng Supplies Ventilation for Gwalia project

AirEng, a nyb subsidiary, has been busy lying the groundwork for mechanical and electrical construction for the Gwalia project. They are providing a turnkey ventilation system for Australia's oldest and deepest golf mine, including primary fans, the electrical power unit, and civil construction systems. One major challenge is getting proper ventilation to the workers underground.

Topics: Fan Performance, Fan Selection, Gwalia, Construction, Mining, AirEng

.png)